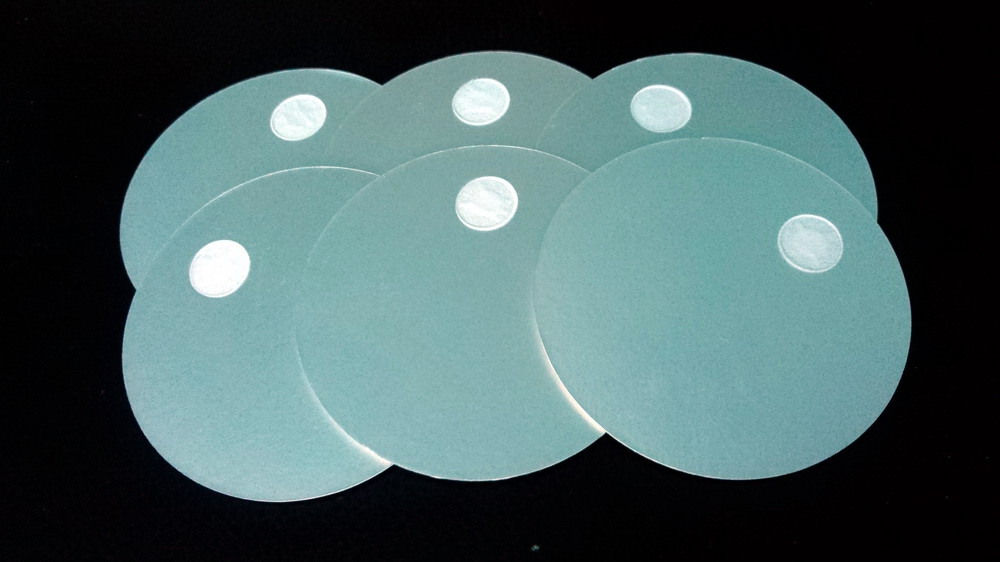

A. Sealed liner, use method

I. Qualified corresponding sealed liner material into the bottle cap, a bottle of contact is screwed on the bottle, aluminum foil, aluminum foil gasket contact bottle must be made sufficiently complete;

II . Adjust the electromagnetic induction sealing device (hand-held electromagnetic induction sealing machine to adjust the time parameters of electromagnetic induction sealing machine, automatic adjustment of power parameter), adjust the parameters according to different material;

III .The bottle upright on the heating head down, do not touch the oral closure, oral closure cap (flat) 2-3MM (distance shall be not more than 5MM), sealing operation;

IV .Sealed, wait 1 minutes, open the bottle cap, check the sealing effect;

Online feedback

Feedback to us, we will contact you shortly. (The following * are mandatory)

- PREVNo record

- NEXTOne-piece top-tabbed liner